|

THE VeloSoleX S 3800 has an Air Filter Housing over the carburettor. It was designed with two small air inlet holes in the Air Filter Housing Base to keep Induction Noise to an absolute minimum. At high RPM the mixture tends to be a little rich due to the air flow being restricted by the two small air inlet holes. So to improve the air flow at speeds above 4000 RPM, the Air Filter Housing must be modified: |

|

|

|

1. Unscrew a 9 mm Bolt & Washer and remove the black Air Filter Housing Cover. |

|

|

2. Remove the aluminum Air Filter Housing Base together with the black Rubber Washer underneath. |

|

|

3. Remove the original Foam Air Filter by prising off the metal Filter Retaining Ring. |

|

|

4. Drill out the two 5.7 mm Inlet Holes in the Air Filter Housing Base using an 8 mm drill. Clean all components with Carburettor Cleaner Spray. Squeeze engine oil lightly into the foam air filter with your fingertips and reassemble all components OR if you wish to fit an S&B Air Filter continue with Step 5. |

|

|

5. Unscrew and remove the brass Main Jet with a 9 mm ring spanner. With the new Air Filter Housing in place the mixture will be too weak particularly at high RPM and the Main Jet hole will require enlargening (from 0.48 mm to 0.5 mm equivalent to a 31 Main Jet) using a 0.5 mm drill held in a miniature drill chuck available from a model shop or Maplins Electronics who stock a Microbox Metric Set (20 drills from 0.3 mm to 1.6 mm, Stock Code: GU87U). The drill must be turned VERY CAREFULLY forwards and backwards by hand, half a turn at a time, otherwise the drill WILL break off in the jet. After drilling clean thoroughly with Carburettor Cleaner Spray making sure that the hole is perfectly clear. Re-fit Main Jet. |

|

|

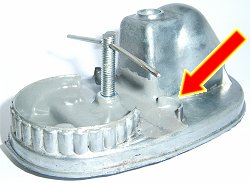

6. Using a small hacksaw, cut the 2 internal Air-Inlet Collars so that only 5 mm remains (one shown with arrow). Smooth any sharp edges with a file. |

|

|

7. Using a small hacksaw, cut a 17 mm wide slot (shown) across the width of the Air Filter Housing Base so that both Air-Inlet Collars and part of the round Air Filter Foam Support is cut through. Smooth any sharp edges with a file. |

|

|

8. Drill a 2 mm diameter hole (shown by top arrow) in the centre of an M6 x 30 mm bolt, about 4 mm from the thread end. Drill a 6 mm hole through the Air Filter Housing Base about 45 mm from the end. Fit the M6 bolt to the base using an M6 locknut and washer (shown by bottom arrow). Hammer in a 64 mm long piece of 2 mm diameter aluminum coat hanger wire into the bolt end using a small hammer and bend wire downwards slightly on both sides. Cover the two original Air-Inlet Collar holes underneath the base with two small pieces of electrical insulating tape. |

|

|

9. Cover the base with JB-Weld Epoxy Resin (shown by arrow) and leave to harden. After the mixture has fully hardened, remove the two pieces of electrical insulating tape. 10. Now, either drill out the air inlet holes in the Air Filter Housing Base using an 8 mm drill and jump to Step 12 OR for a even better airflow (but also increased Induction Noise) continue with Step 11. |

|

|

11. Remove the sticker from the Air Filter Housing Cover. Cut a circumferential slot 95 mm long by 17 mm wide in the Air Filter Housing Cover, 15 mm up from the base. Smooth the corners of the slot with a file. Glue a 105 mm long by 25 mm wide rectangular section of black metal gauze (pierced with approximately 1.5 mm diameter holes) inside the Air Filter Housing Cover using High-Temperature Epoxy Resin. Use wire to hold the gauze in place until the High-Temperature Epoxy Resin has hardened. |

|

|

12. Cut a piece of Filter Material (75 mm wide by 35 mm high by 17 mm thick) from a new S&B Air Filter. Oil it with S&B Air Filter Oil and fit it into the slot in the Air Filter Housing Base so that the coat hanger wire cross restrains it against the centre of the housing. Reassemble all components. |

VELOSOLEX is a trademark of VELOSOLEX

AMERICA, LLC

e-SOLEX, SOLEX and SOLEXINE

are trademarks of Societie SINBAR

- Groupe CIBLE